More steel strip products

- Polished blue,bright,yellow steel strip

- Hot rolled steel strip

- CK67,C67S,C70S,C75S high carbon spring steel strip

- C50S, C55S,C60S medium carbon steel strip

- 65mn spring strip steel

- Rolling shutter spring steel strip

- Bandsaw blades application steel strip

- Hardened and Tempered Steel Strip

- Cold Rolled annealed steel strip

- Tempered|heat treatment spring steel strip

Related articles

Contact us

-

SHANGHAI GOLDEN BRIDGE INDUSTRIES CO.,LTD

CONTACT:Grace.Chen

TEL:+86-15879557758

EMAIL:sales@sh-gbindustries.com

WHATSAPP:+86-15879557758

grace.chen@sh-gbindustries.com

ADD:NO.8 Building, NO.1098 ChuanSha Road,PuDong New Area, Shanghai, China

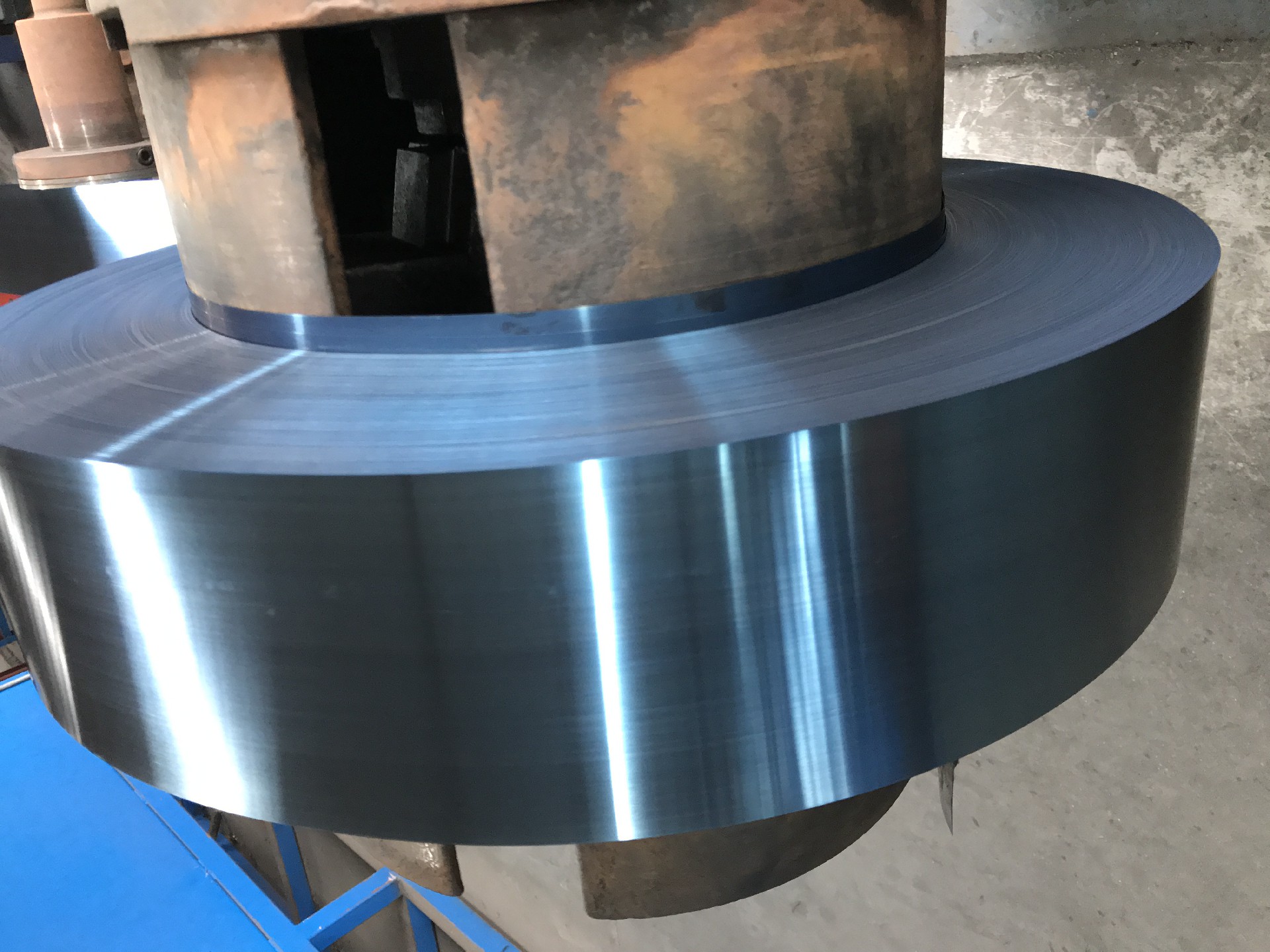

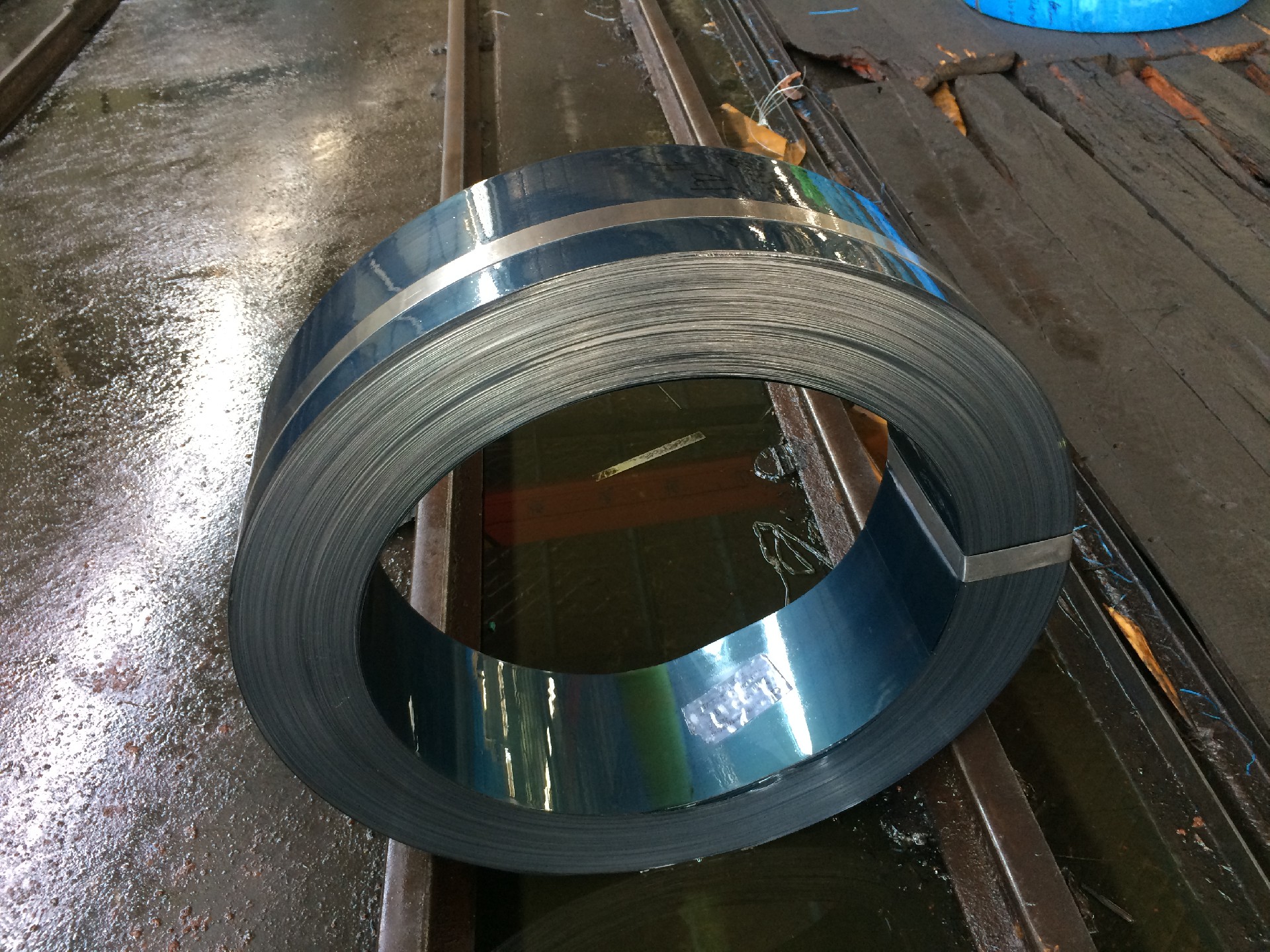

Hardened and Tempered Steel Strip

Description

Hardened and Tempered Carbon Steel Strip is produced using a heat treatment process that

achieves strength through a controlled heating and cooling process.

Hardened and Tempered Steel Strip is used in many applications including saws, cutting tools as well as springs.

Production Range Hardened and Tempered

Quality standards EN 10132

Thickness from 0.30mm to 2.5mm

Width from 10mm to 300mm

Grade: C50/C60/CK75,C70,CK67,65MN,C75Cr1..

Surface appearance:

Unpolished Semi Bright: Hardened and tempered non-oxdised where semi bright surface is required on requested hardness.

Polished Bright: Polished after hardening and tempering.

Polished Blue: Colouring in blue after polishing.

Polished Yellow: Colouring in yellow after polishing.

Hardness: 29HRC-60HRC

Hardened and Tempered Steel Strip Application

Hardened and Tempered Steel Strip has a wide range of applications in industrial manufacturing, typically in applications that require high strength and hardness. Here are some common application areas for hardened and tempered steel strips:

Tool Manufacturing: Hardened and tempered steel strips are often used in the manufacture of cutting tools such as saw blades, knives, and planer blades. Their high hardness and strength allow these tools to maintain sharpness and have a longer lifespan during cutting and shaping tasks.

Springs: Springs require specific hardness and strength properties to maintain their elasticity and resilience. Hardened and tempered steel strips are used to manufacture various types of springs, including compression springs, tension springs, and torsion springs.

Clockwork Mechanisms: Clockwork mechanisms, including those in various mechanical and timekeeping applications, often utilize hardened and tempered steel strips due to their precision and reliability.

Tool Production: Tools like pliers, wrenches, and hammers typically need to withstand heavy pressure and cutting forces during use. Components made from hardened and tempered steel strips provide durability and reliability to these tools.

Automotive Industry: In the automotive manufacturing sector, hardened and tempered steel strips are commonly used to make brake pads, clutch plates, transmission components, and other parts that require high wear resistance.

Cooler Manufacturing: These strips are employed in the production of various types of coolers, including radiators and automotive heat exchangers. These components need to maintain strength and shape stability under high temperatures and pressures.

Lock Manufacturing: Locks and lock cores often require high wear resistance and resistance to cutting. Hardened and tempered steel strips are used to manufacture lock cores and other critical components.

Construction Industry: In the construction and structural sectors, hardened and tempered steel strips are used to manufacture various connectors, supports, and reinforcement materials to enhance the strength and durability of structures.

In summary, hardened and tempered steel strips are critical engineering materials due to their high strength, hardness, and wear resistance. They are used in various industries to manufacture high-performance components and tools.

Hardened and Tempered Steel Strip Faq?

Certainly! Here are some frequently asked questions (FAQ) about hardened and tempered steel strips:

1. What is hardened and tempered steel strip?

Hardened and tempered steel strip is a type of steel strip that has undergone a specific heat treatment process to achieve a combination of high hardness, strength, and resilience. This treatment involves heating the steel to a critical temperature and then quenching it in a controlled manner, followed by tempering to achieve the desired properties.

2. What are the main characteristics of hardened and tempered steel strips?

Hardened and tempered steel strips are known for their high hardness, excellent wear resistance, good tensile strength, and the ability to maintain their shape and performance under heavy loads and repeated stress.

3. What are the common applications of hardened and tempered steel strips?

These strips find use in various industries, including tool manufacturing, spring production, clockwork mechanisms, automotive components, cooler manufacturing, lock production, and construction applications.

4. How is the hardness of hardened and tempered steel strips measured?

The hardness of these strips is typically measured using the Rockwell hardness scale (HRC), which quantifies the material's resistance to indentation or penetration.

5. What is the purpose of tempering in the heat treatment process?

Tempering is a crucial step in the heat treatment process of hardened and tempered steel strips. It reduces the brittleness that can result from the initial hardening process, improving toughness and preventing the steel from becoming too brittle.

6. Can hardened and tempered steel strips be customized for specific applications?

Yes, these strips can be customized in terms of hardness, thickness, and dimensions to meet the specific requirements of different applications.

7. What are the advantages of using hardened and tempered steel strips?

Hardened and tempered steel strips offer exceptional durability, wear resistance, and performance, making them ideal for applications where strength and hardness are critical.

8. How are hardened and tempered steel strips stored and handled to maintain their quality?

These strips should be stored in a dry environment to prevent rusting. Care should be taken during handling to avoid excessive bending or deformation before they are used.

9. Are there different grades of hardened and tempered steel strips available?

Yes, various grades of steel are used for these strips, and the choice of grade depends on the specific application and performance requirements.

10. Where can I source high-quality hardened and tempered steel strips for my applications?- Reputable steel suppliers and manufacturers often offer a range of hardened and tempered steel strips. It's important to work with a trusted supplier to ensure the right material for your specific needs.

These FAQs provide an overview of hardened and tempered steel strips and their applications. For more detailed information or specific inquiries, consulting with a steel expert or supplier is advisable.